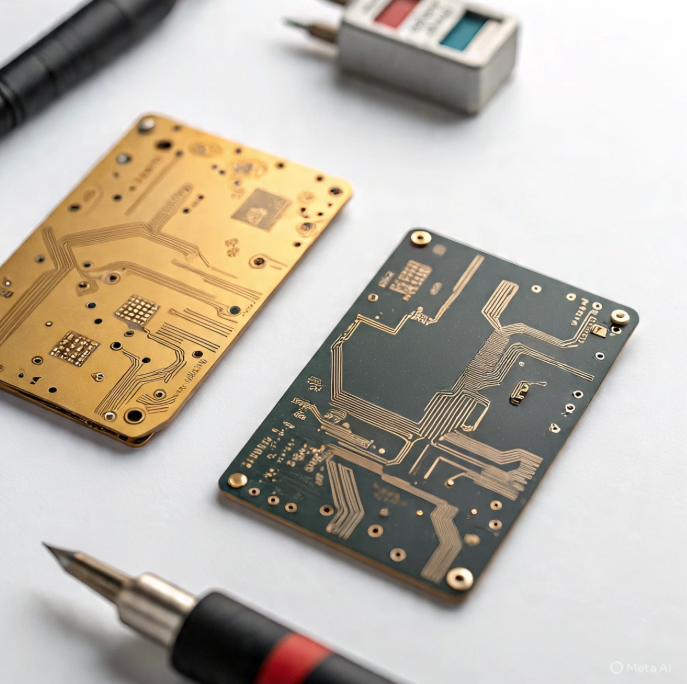

RF PCB and Microwave PCB: High-Frequency Rogers PCB Manufacturing Services

In today’s rapidly evolving electronics landscape, precision and reliability are crucial, especially for high-frequency applications. Whether it’s telecommunications, aerospace, or advanced radar systems, the demand for high-performance RF PCB boards has never been higher. As a high frequency PCB manufacturer, we specialize in delivering superior microwave PCB fabrication solutions that meet the strictest industry standards. From prototypes to full-scale production, our Rogers PCB solutions ensure optimal performance and reliability.

What Is an RF PCB and Why It Matters

RF PCBs, or radio frequency printed circuit boards, are designed to handle high-frequency signals with minimal loss. Unlike standard PCBs, RF boards demand careful consideration of signal integrity, impedance control, and dielectric properties. A small mistake in material choice or trace design can lead to signal degradation, which can affect the performance of the entire system.

From my experience working with clients in telecommunications, I’ve seen firsthand how a well-designed RF PCB board can significantly improve device efficiency and reduce interference. Choosing the right Rogers PCB material, known for its low dielectric loss and stable performance across high frequencies, is a key factor in achieving this.

Advantages of High-Frequency PCB Manufacturing

When you opt for microwave PCB fabrication, you unlock several advantages that are critical for modern electronics:

Precision Impedance Control

For high-frequency circuits, maintaining consistent impedance is essential. Variations can lead to signal reflection, power loss, or interference. Our advanced fabrication processes ensure tight impedance control, giving your devices a competitive edge.

Superior Signal Integrity

High-frequency applications demand clean signal transmission. Using premium Rogers PCB materials, we minimize signal distortion, which is especially important for applications such as radar, satellite communication, and 5G devices.

Rapid Prototyping and Scalable Production

Whether you need a quick prototype or a large production run, our services are flexible and reliable. From uploading your Gerber files to receiving a fast, accurate quote, we make the process seamless. Personally, I’ve found that having a high-frequency PCB manufacturer who can quickly transition from prototype to production saves both time and costs, which is crucial for startups and large enterprises alike.

See also: How Tech Is Reshaping the Music Industry

Applications of RF and Microwave PCBs

RF and microwave PCBs are not limited to a single sector. They play a pivotal role in various industries:

Telecommunications

High-speed data transfer and wireless communication systems depend on microwave PCB fabrication for optimal performance. Devices like smartphones, base stations, and IoT modules rely heavily on precision PCB design.

Aerospace and Defense

Radar systems, navigation equipment, and military communication devices require high-frequency PCBs with unmatched reliability and signal integrity. I’ve personally collaborated with defense contractors who emphasized that even minor imperfections could compromise entire systems, highlighting the importance of choosing a trusted Rogers PCB supplier.

Medical Electronics

From imaging systems to diagnostic tools, RF PCB boards ensure accuracy and consistency in medical applications. The precision we provide can make a difference in critical healthcare solutions.

Why Choose Us as Your High-Frequency PCB Manufacturer

At the core of our service is a commitment to quality and precision. Here’s why clients prefer our Rogers PCB and microwave PCB manufacturing services:

Expert Fabrication Services

Our team specializes in microwave PCB fabrication, ensuring every board meets strict industry requirements. We combine experience, cutting-edge technology, and attention to detail for every project.

Material Excellence

We use high-quality Rogers PCB materials, known for their stability, low loss, and high-frequency performance. This ensures that your circuits operate efficiently even under demanding conditions.

Efficient Prototyping

Our fast-turn prototyping allows clients to test designs before full production. Upload your Gerber files today, and receive a reliable, prompt quote. I’ve personally found this step invaluable for catching potential design issues early, saving both time and money in the long run.

Comprehensive Support

From design consultation to after-sales support, our team guides you through every step. Our approach combines technical expertise with practical experience, ensuring your project’s success.

Key Considerations in Microwave PCB Design

Designing RF PCBs and microwave PCBs requires careful attention to detail. Here are some key considerations:

Trace Layout and Signal Paths

High-frequency signals are sensitive to layout imperfections. Proper trace width, spacing, and grounding help maintain signal integrity and reduce noise.

Dielectric Material Selection

Choosing the right Rogers PCB material is critical. Factors like dielectric constant, thermal stability, and loss tangent determine overall performance.

Layer Stack-Up

Multi-layer boards provide better routing flexibility and isolation between signal layers. This is especially important in complex designs where multiple high-frequency signals coexist.

Thermal Management

High-frequency boards often carry higher currents or operate at high power levels. Adequate heat dissipation techniques prevent performance degradation or component failure.

My Personal Take on RF PCB Manufacturing

Having worked closely with engineers and product developers, I’ve noticed that many companies underestimate the importance of choosing the right high-frequency PCB manufacturer. A reliable partner doesn’t just fabricate the board—they ensure your designs perform as intended. In my experience, working with a manufacturer who emphasizes microwave PCB fabrication precision makes a noticeable difference in the final product’s efficiency and reliability.

Get Started with Your RF PCB Project

Whether you’re looking for a prototype or full-scale production, partnering with a trusted Rogers PCB supplier is the first step toward success. Our process is simple:

- Upload your Gerber files.

- Receive a fast, accurate quote.

- Benefit from high-quality microwave PCB fabrication with tight impedance control and superior signal integrity.

We understand the stakes in high-frequency applications, and our dedication to precision ensures your projects are in capable hands.

Conclusion

In the competitive world of high-frequency electronics, choosing the right high-frequency PCB manufacturer is crucial. From RF PCB boards to microwave PCBs, our advanced Rogers PCB fabrication services offer the precision, reliability, and performance your projects demand. Whether you are developing the next-generation communication device, radar system, or medical electronics solution, our expertise ensures your designs perform at their best. Upload your Gerber files today and experience the difference of working with a dedicated, professional, and experienced RF and microwave PCB manufacturer.